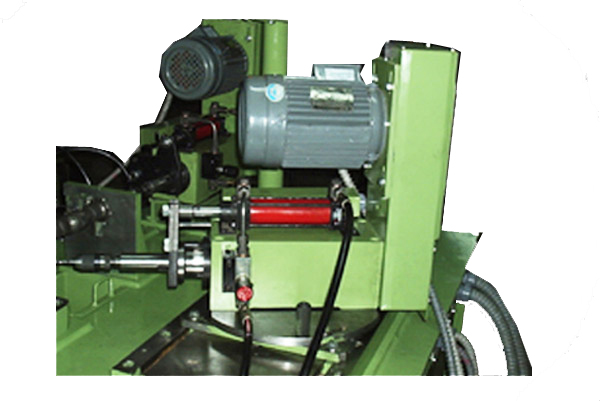

Spepurmac Engineering Services, located in Satara, Maharashtra, India is the Manufacturer, Supplier, Exporter, Designer, Service Provider of Quill Feed Drilling Heads, Quill Feed Drilling Machines, Drills, Drilling Machines, A compact design drilling head having facility to drill holes to the required depth through control of hydraulic cylinder with variable speed, feed to achieve high productivity.

• Capacity -12 MM in steel

• Feed - Hydraulic / stroke 100 MM

• Spindle Speeds - 9 speeds thro step pulleys

• Available in - M.T. Taper / Adjustable adopter type. Parallel bore / collect clamping

• Available as per customer requirement.

Quill Feed Drilling Heads

Quill feed drilling heads are essential tools used in various industries for precision drilling applications. These heads are designed to provide controlled feed and accurate hole drilling, making them highly popular in machining, metalworking, woodworking, and other manufacturing processes.

Quill feed drilling heads are specialized tools used in drilling operations to create holes with precision and efficiency. These heads are commonly attached to milling machines, drill presses, or other machining equipment, providing controlled movement and depth adjustment during the drilling process. With their ability to perform accurate and repeatable drilling, they are indispensable for tasks that demand high-quality results.

Key Features of Quill feed drilling heads:

- a. Adjustable Quill Feed: Quill feed drilling heads come with adjustable mechanisms, allowing operators to control the drilling depth and feed rate. This feature ensures consistent and precise hole creation in various materials.

- b. Versatility: These drilling heads can accommodate different drill bit sizes and types, making them versatile tools suitable for a wide range of applications. From small-scale hobbyist projects to heavy-duty industrial tasks, quill feed drilling heads deliver optimal performance.

- c. Swivel Base: Some drilling heads feature a swivel base, enabling users to set the drilling angle, making them ideal for projects that require angled or slanted holes.

- d. Integrated Coolant System: Many modern quill feed drilling heads are equipped with an integrated coolant system that helps prolong the tool's life and ensures efficient heat dissipation during extended drilling operations.

- e. Speed and Feed Controls: Some advanced models offer speed and feed controls, allowing users to adjust the rotational speed and feed rate according to the specific material and drilling requirements.

Applications industries for Quill feed drilling heads:

- 1. Metalworking Industry: Quill feed drilling heads are commonly used in metalworking applications, such as drilling holes in metal workpieces, machining centers, and CNC milling machines. They are especially useful for producing precise and consistent holes in metal components.

- 2. Automotive Industry: In the automotive sector, quill feed drilling heads are employed for various tasks, including drilling holes in engine blocks, cylinder heads, brake components, and chassis parts. These heads help ensure the accurate alignment and positioning of holes for critical automotive components.

- 3. Aerospace Industry: The aerospace industry relies on quill feed drilling heads for drilling holes in aircraft components, such as engine parts, wing structures, and landing gear. The precision and repeatability of these heads are crucial for maintaining the safety and integrity of aerospace components.

- 4. Construction Industry: Quill feed drilling heads find applications in the construction sector for drilling holes in structural components like beams, columns, and concrete elements. They are used in construction machinery like drilling rigs to ensure consistent and precise hole placement.

- 5. Woodworking Industry: In woodworking, quill feed drilling heads are used for drilling holes in wood panels, furniture components, and cabinetry. These heads help achieve uniform hole spacing and depth control, enhancing the overall quality and appearance of the woodwork.

- 6. Electronics Industry: Quill feed drilling heads are used in electronics manufacturing to create precise holes in printed circuit boards (PCBs) and electronic components. The accurate hole placement is essential for ensuring proper PCB functionality and reliability.

- 7. Medical Device Industry: In medical device manufacturing, quill feed drilling heads are utilized for drilling holes in various medical equipment components, such as orthopedic implants, surgical instruments, and dental devices.

- 8. Oil and Gas Industry: The oil and gas sector employs quill feed drilling heads in drilling rigs for tasks like wellbore drilling, casing, and cementing operations. These heads play a vital role in efficient and accurate drilling processes in oil and gas exploration and production.

Overall, quill feed drilling heads are versatile tools used in industries where precision drilling and controlled depth are crucial for the quality and performance of the end products. They enhance productivity, reduce manual labor, and contribute to the overall efficiency of the manufacturing or drilling processes in these industries.

Quill Feed Drilling Heads Safety Precautions:

While using quill feed drilling heads, operators must follow safety guidelines to prevent accidents and ensure optimal results. Some key safety measures include wearing appropriate personal protective equipment (PPE), securing workpieces properly, and familiarizing themselves with the equipment's operating instructions.

Quill feed drilling heads are invaluable tools in various industries, providing the precision and control needed for accurate hole drilling in diverse materials. Their versatility, adjustable features, and reliability make them a must-have for any workshop or manufacturing facility seeking to achieve high-quality drilling results efficiently and safely.

Factors to Consider When Choosing Quill Feed Drilling Heads

- Material compatibility and cutting speeds.

- Capacity and range of the drilling heads.

- Consideration for automated and CNC machining.

Maintenance and Care Tips

- Regular inspection and cleaning procedures.

- Lubrication and cooling requirements.

- Proper storage practices for prolonged tool life.

Best Practices for Using Quill Feed Drilling Heads

- Proper setup and alignment techniques.

- Selecting the right cutting tools and drill bits.

- Tips for optimizing feeds and speeds.

Troubleshooting Common Issues

- Identifying and resolving drilling inconsistencies.

- Dealing with tool wear and breakage.

- Troubleshooting misalignment and vibration problems.

Quill feed drilling heads are essential tools for enhancing drilling operations across various industries. By understanding their mechanics, applications, and best practices for use, manufacturers can maximize their efficiency, precision, and overall productivity. Remember to prioritize safety and regular maintenance to ensure the longevity of these valuable tools. Invest in high-quality quill feed drilling heads and integrate them into your machining processes to take your operations to the next level.