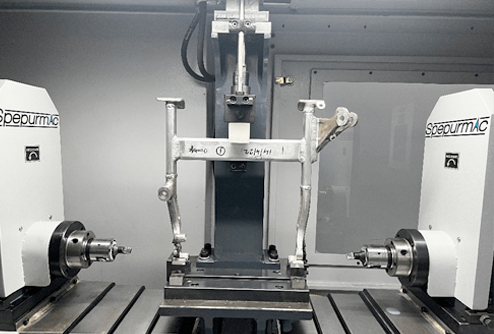

Double end boring machines are versatile tools used in various industries for precision drilling and boring operations. These machines are designed to drill from both ends of a workpiece simultaneously, improving efficiency and accuracy.

Some of the common application industries for double end boring machines include:

- 1. Woodworking: Double end boring machines are widely used in the woodworking industry for drilling holes in furniture components, cabinet parts, wooden panels, and other wood products. These machines can efficiently bore holes for dowels, screws, and other fasteners.

- 2. Furniture Manufacturing: In furniture manufacturing, double end boring machines play a crucial role in creating joints and connections for assembling furniture pieces. They are used to drill precise holes for dowels, connectors, and other assembly components.

- 3. Cabinet Making: Cabinet makers use double end boring machines to create holes for shelves, drawer runners, and other hardware fittings. The machines can accurately drill holes in a repetitive manner, ensuring consistent results for mass production.

- 4. Door and Window Manufacturing: Double end boring machines are employed to bore holes for hinges, locks, and other hardware components in door and window frames. They ensure proper alignment and fit of the hardware.

- 5. Metalworking: In metalworking industries, double end boring machines are used to create holes in metal workpieces, such as engine blocks, automotive parts, and industrial components. They are often utilized in high-precision applications where accuracy is crucial.

- 6. Automotive Industry: Double end boring machines find applications in the automotive sector for manufacturing engine blocks, cylinder heads, and other critical engine components. They enable precise drilling and ensure uniformity in the engine assembly process.

- 7. Aerospace Industry: Aerospace manufacturers use double end boring machines to produce components for aircraft and spacecraft. These machines help in drilling holes for various parts, including fuselage sections, wings, and landing gear components.

- 8. General Machinery Manufacturing: Various industries that produce machinery and equipment utilize double end boring machines for drilling holes in machine frames, structural components, and other parts.

- 9. Railway and Transportation: In the railway and transportation industry, double end boring machines are used for manufacturing parts of trains, trams, and other rail vehicles. They help in creating precise holes for assembling various components.

- 10. Construction: Double end boring machines are utilized in construction industries for drilling holes in wooden beams, concrete formwork, and other construction materials.

Overall, double end boring machines are valuable tools for any industry that requires precision drilling and boring operations. Their ability to drill from both ends simultaneously makes them efficient, reduces production time, and ensures consistent results across a range of applications.

Double end boring machines offer a powerful solution for woodworkers seeking precision, efficiency, and increased productivity. From furniture manufacturing to joinery work, these machines play a crucial role in achieving high-quality results.

Invest in a double end boring machine today to elevate your woodworking projects to new heights.

Contact us to explore the best machine options for your specific needs and take your woodworking skills to the next level!